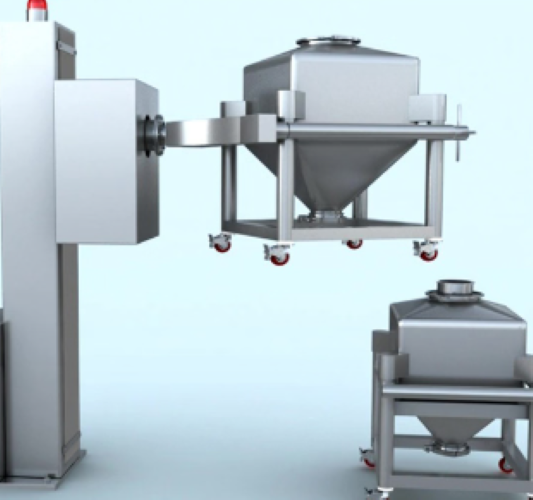

Bin Blender

Bin Blender Specification

- Usage & Applications

- INDUSTRIAL

- Type

- Bin Blender

- Material

- STAINLESS STEEL 304

- Capacity

- From 25L to 3000L Ltr

- Computerized

- No

- Control Mode

- Semi-Automatic

- Voltage

- 220-440 Volt (v)

- Color

- Silver

- Warranty

- 1 Year

Bin Blender Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- AHMEDABAD

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 10 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Certifications

- ISO

About Bin Blender

KEDMECH GLOBAL PVT LIMITED IS SERVING IN PHARMA INDUSRTY OF LAST DECAY.

IT IS A PHARMA GRANULATION LINE MANUFACTURING COMPANY FOR GIVING A BEST MACHINE ON BEST PRICE. AND WE GIVING TO GOOD SERVICE TILL CUSTOMER SATISFACTION.

Engineered for Versatile Industrial Applications

The Bin Blender is crafted to serve diverse industries needing uniform powder and granule mixing. Its wide capacity range allows seamless adaptation for small batch processing or large-scale production, ensuring optimal blending in every cycle. Constructed from Stainless Steel 304, it guarantees product safety and longevity, weighing durability and sanitation equally for sensitive manufacturing environments.

Advanced, User-Friendly Semi-Automatic Operation

Designed for simplicity and efficiency, the semi-automatic control mode reduces manual effort while maintaining precise mixing processes. No complex programming or computerization is involved, enabling quick set-up and straightforward operation for staff. The 220-440V voltage flexibility ensures compatibility with standard industrial power supplies, making integration into existing workflows smooth and stress-free.

FAQs of Bin Blender:

Q: How does the Bin Blender operate and what is its blending process?

A: The Bin Blender uses a tumbling action to uniformly mix powders and granules inside a stainless steel bin. Its semi-automatic operation requires minimal input from the userjust load the materials, select the cycle, and the unit completes the mixing using controlled rotational movements for consistent results.Q: What types of materials can be blended with this machine?

A: This Bin Blender is ideal for mixing dry powders and granulated substances commonly found in the pharmaceutical, chemical, and food industries. Its Stainless Steel 304 construction ensures compatibility with a broad range of ingredients, including sensitive and contamination-prone materials.Q: When is it best to use a Bin Blender over other mixing equipment?

A: A Bin Blender is recommended when you require gentle yet thorough mixing of bulk powders or granules, especially when product contamination must be avoided and batch traceability is important. Its design minimizes residue and cross-contamination, suitable for industries where product purity matters.Q: Where can the Bin Blender be installed, and is it suitable for my facility?

A: The Bin Blender is manufactured and supplied in India and can be integrated into any industrial setting with the required floor space and power supply (220-440V). Its ease of installation and adaptability to various batch sizes make it suitable for small or large-scale operations alike.Q: What benefits does using a Bin Blender offer for industrial production?

A: Using a Bin Blender ensures homogenous mixing, reduces operator effort due to semi-automatic controls, and minimizes contamination risks. The wide capacity range, user-friendly interface, and stainless steel construction contribute to increased productivity and reliable quality control in your manufacturing process.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Blender Machine Category

Blender Machine

Price 90000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control Mode : Manual

Warranty : 5 7 Years

Material : Stainless Steel

Computerized : No

Ribbon Blender

Price 90000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Control Mode : SemiAutomatic

Warranty : 1 Year

Material : STAINLESS STEEL

Computerized : No

V Blender

Price 180000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Control Mode : SemiAutomatic

Warranty : 1 Year

Material : Stainless Steel

Computerized : No

Octagonal Blender Machine

Price 100 INR / Unit

Minimum Order Quantity : 1 Unit

Control Mode : Manual

Warranty : 5 7 Years

Material : Stainless Steel

Computerized : No